Why Mega-Projects Fail Long Before Execution Begins

In every major project, there is a document that quietly determines the difference between predictable delivery and catastrophic failure: the Basis of Estimate. Inside it, dozens of assumptions outline the physical, human, and logistical constraints that define whether the plan is feasible.

And yet—almost universally—these assumptions go unread.

Executives fixate on the final number.

Project Controls fixates on the schedule.

Delivery teams fixate on execution.

But the conditions that make those numbers achievable—the throughput limits, congestion risks, shift requirements, laydown capacity, staging constraints—are frequently ignored.

This is not a minor oversight.

It is the root cause of systemic project failure.

Because assumptions are not “fine print.”

They are the physics of the project.

When organizations skip the assumptions, they are not skipping paperwork.

They are skipping reality.

1. The Costliest Habit in Project Delivery: Outcome Over Physics

Most project failures begin with a subtle but deadly behavioural pattern:

Outcome obsession → Physics denial → Predictable collapse.

Teams want predictable costs and predictable schedules, so they gravitate toward the optimistic scenario—the one where all conditions align perfectly and no operational limitations exist.

But projects do not operate in perfect environments. They operate in:

Limited space Restricted access Congested zones Finite laydown areas Controlled gate capacity Human productivity limits Staging interdependencies Shift pattern constraints

These limitations directly shape cost, productivity, and schedule feasibility. Ignoring them does not make the project more “agile” or “efficient.” It simply makes the plan fictitious.

2. Assumptions Aren’t Administrative — They Are Structural

Every assumption exists for a reason.

They’re early warnings of what the system can and cannot support.

Examples include:

Throughput limits: labor cannot be infinitely accelerated. Congested conditions: physical space dictates crew density. Laydown capacity: material flow depends on actual yard space. Staging constraints: work sequencing depends on zone readiness.

If the plan requires ignoring these constraints, the plan is flawed—not the estimate.

Yet many organizations continue approving plans that violate their own assumptions, then express shock when productivity collapses in the field.

Assumptions are not hypothetical.

They are the boundary conditions of reality.

3. The Most Expensive Phrase in Project Management: “We’ll Figure It Out”

When assumptions get ignored, organizations resort to compensatory behaviour:

“We’ll make it work.” “The schedule says we can do it.” “We’ll push harder.” “We’ll adjust during execution.” “We’ll deal with constraints later.”

Later always comes. And it comes with:

Unrecoverable productivity losses Missed milestones Increased congestion and trade stacking Inefficient shift patterns Gate and access bottlenecks Rework, re-baselines, and firefighting Compromised safety margins Loss of stakeholder confidence Burned-out teams and leadership fatigue

These are not unexpected events.

They are the direct consequences of assumptions the organization chose not to honour.

4. The CRU Lens: Assumptions Are the Earliest Indicators of Collapse

Resource-Centric Planning and Whitespace Management expose a truth the industry rarely confronts:

Assumptions are the earliest signals of system overload.

When an estimator notes:

“Assumed gate throughput: 600 persons/hour” “Assumed staggered shifts to prevent crew overlap” “Assumed laydown limit: 42 trailers” “Assumed max simultaneous occupancy per zone: 40 workers”

they’re not covering themselves—they’re describing the fragile balance required to keep the project operational.

If leadership ignores these constraints, the organization is not undertaking risk.

It is manufacturing failure.

The estimate does not break.

The system breaks.

5. If You Don’t Control Assumptions, They Will Control You

Here is the operational truth:

Assumptions don’t disappear when you ignore them.

They become your consequences.

Ignoring constraints during planning forces you to confront them during execution:

Congested workfaces Trades competing for space Delayed scaffolding availability Access and egress bottlenecks Unachievable shift patterns Conflicting zone readiness Declining productivity curves Budget overruns and delivery pressure

You can defer these constraints,

but you cannot escape them.

6. What High-Performance Organizations Do Differently

Project-mature organizations treat assumptions as first-class citizens in planning and governance.

They:

Read assumptions early Stress-test them against real capacity Link them to throughput, access, and spatial feasibility Map them directly to shift design and workforce density Treat the Basis of Estimate as a controlling document Hold leadership accountable to the physical realities of the site

They don’t “hope for best-case.”

They design for real-case.

This is the difference between a predictable project and a heroic one that burns people out and still arrives late.

7. The Leadership Imperative: Read the Truth Before You Approve the Story

Assumptions are uncomfortable because they expose limits.

But limits are not weaknesses—they are guardrails.

Failing to read them does not make a project stronger.

It makes the landing harder.

If leaders want fewer surprises, fewer overruns, and fewer crisis meetings, the solution is straightforward:

Start reading the assumptions.

Or start owning the consequences.

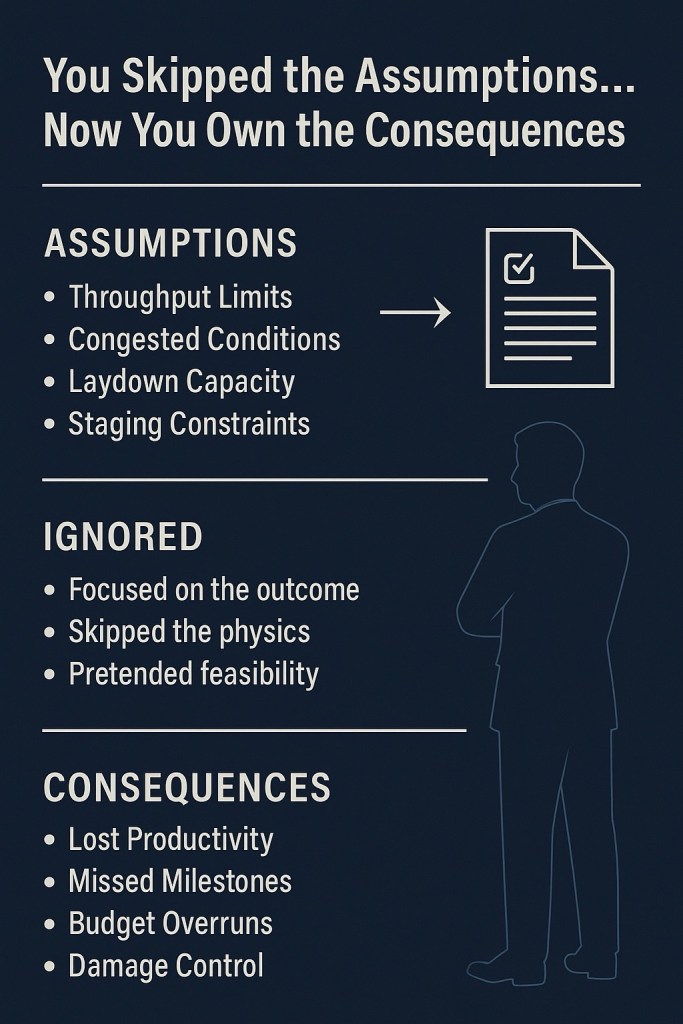

The visual says it plainly:

You skipped the assumptions… now you own the consequences.

It’s time to stop skipping.